Back pressure flap ProFlap: Explosion decoupling inside connected ductwork to protect separators

Numerous processes can create explosive dust/air mixtures inside industrial systems (i.e., dust collectors, mixing machines, fluid bed granulators, mills, etc.). If ignition sources cannot be excluded due to process conditions, these systems are often equipped with constructive explosion protection measures such as pressure relief or pressure suppression. In this instance, connected ductwork is decoupled from containers to be protected so that no flames or explosion pressure can be transferred into other areas.

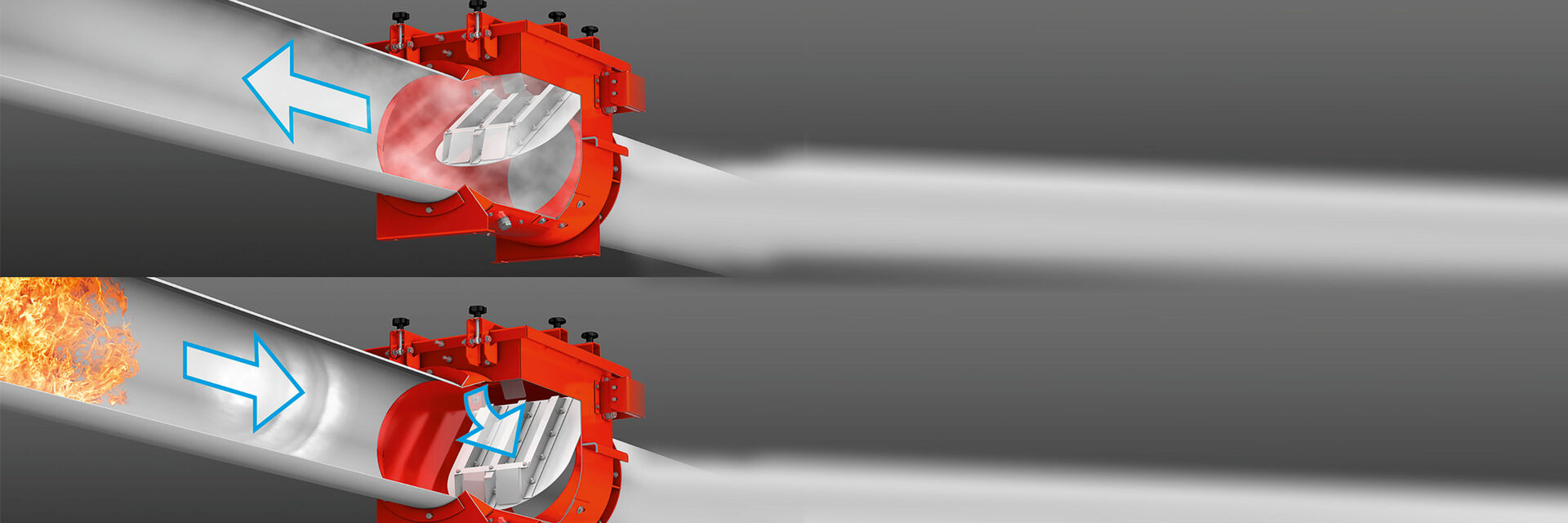

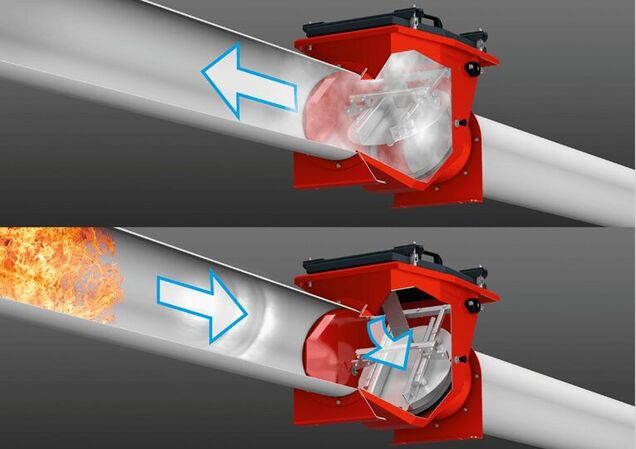

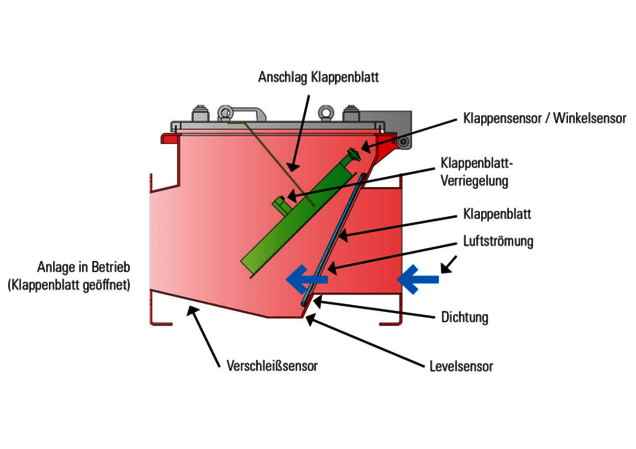

Reliable protection against explosion pressure and explosion flames

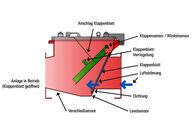

Keller Lufttechnik developed the back pressure flap series ProFlapIII for effective explosion decoupling for most sectors of industry. The ProFlapIII is certified as a protective system according to EU Guideline 2014/34/EU (ATEX 114) and is approved for decoupling of dust explosions of organic and mineral dusts.

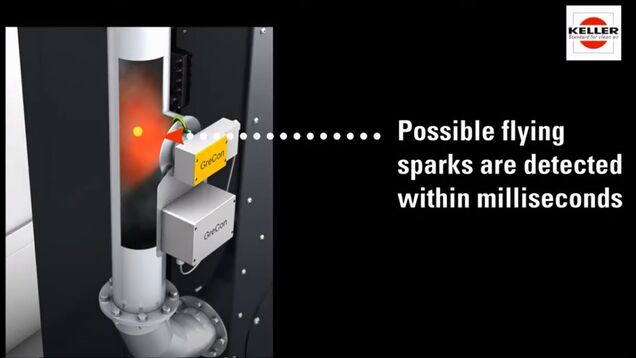

ProSens ignition source monitor: Avoiding an explosive environment

Avoiding an explosive environment seems to be the most obvious protective measure to successfully prevent a dust explosion - but not all processes are suitable for it.

Aluminum processing with MQL, for example, is interrupted during the cleaning of filter elements. During cleaning, no ignition source can gain entry.

Furthermore, the suction air duct is monitored by a spark sensor. If an ignition spark entry is detected, the PLC can be set to prevent the next pending cleaning of the filter elements, thereby averting an explosive situation.

The ProSens-System is suitable for organic and metal dusts.

Flameless pressure relief ProVent: Neutralizing of dust explosions for indoor installation

If preventive explosion protection measures are not sufficient to prevent for an explosion and the consequences, the explosion protection should be by constructive measures. The protection concept ProVent allows a flameless explosion pressure relief for organic dusts. .

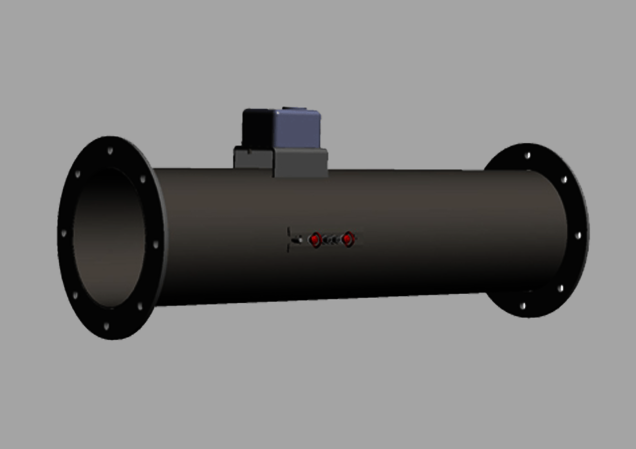

ProPipePlus: Flameless pressure relief for metal dusts

ProPipePlus ensures safe explosion pressure relief inside closed rooms by means of the patented flame barrier and dust separation. The special stainless steel construction is approved for metal dust, and since the end of 2013 an aluminum version is available, as well.

Indoor installation - no safety distance required

The patented ProPipePlus system does not require a protection zone. For aluminum dust, a special version is available.

ProFlow: Air flow monitoring is for explosion protection

The air flow of any individual system can be monitored by ProFlow. If the desired nominal air flow is not achieved, an alarm is displayed on the machine's control, after a brief time delay. The creation of an explosive environment is averted, in addition to any caked-on deposits inside the ductwork, which can pose a fire hazard. Additionally, operators are protected from contaminated air when opening the hatches.

Further information:

Brochure "explosion protection according to ATEX guidelines"