High operational safety ensures trouble-free and energy-efficient performance

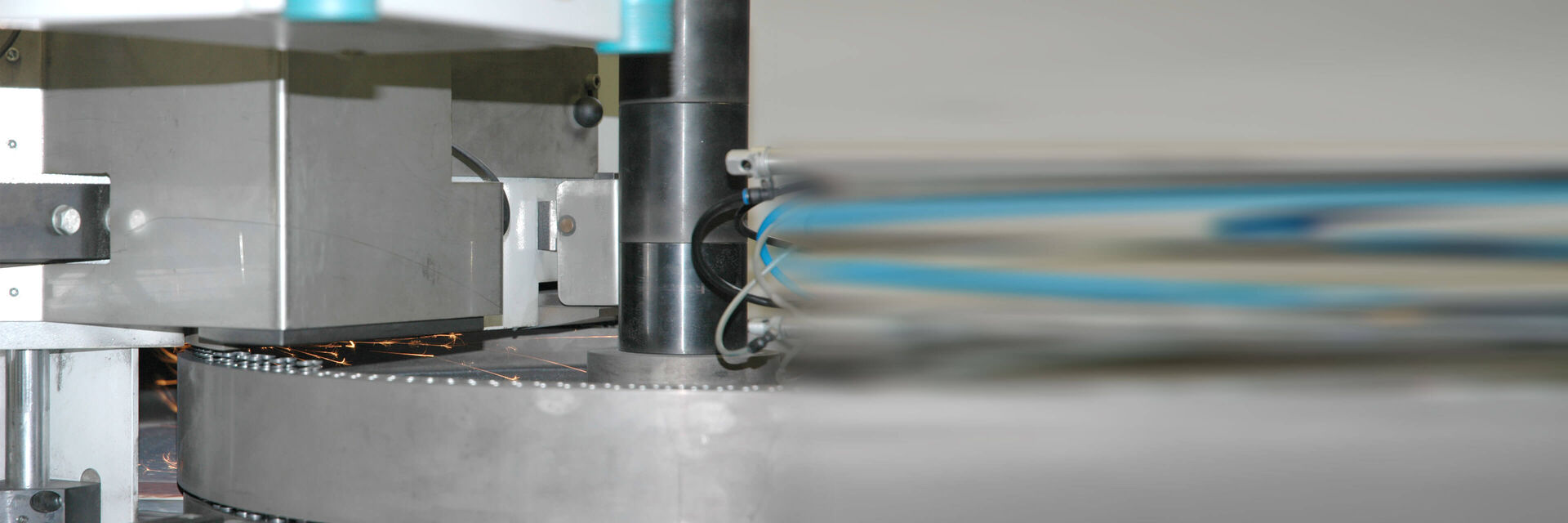

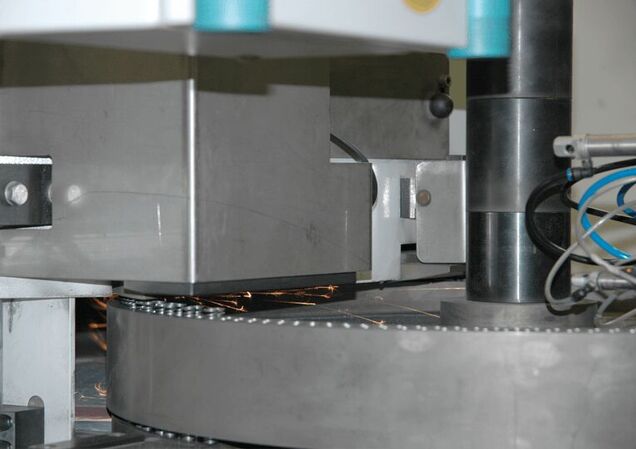

Spring grinding generates particulate emissions which are not avoidable even in the use of state-of-the-art machinery. The capture, extraction and separation processes involved in production are regulated for operational and occupational safety and environmental protection reasons. The handling of fine dust is further complicated by the presence of toxic and carcinogenic health hazards. Increasing requirements for energy efficiency set additional demands that must also be taken into consideration.

Efficient and robust dry separators for continuous operation

Dry separators in the VARIO or PT series are optimally suited for the extraction of dust from spring grinding processes. The KLR filters are equipped with a PTFE membrane to achieve a residual dust content of < 0.1 %, and enable clean air recirculation of purified air into the workplace without additional secondary filters. This substantially contributes to increased energy efficiency. However, the TRGS 560 regulation regarding air recirculation must be followed. The continuous compressed air cleaning of the filters ensures continuous operational safety.

References spring end grinding

These customers rely on our extraction systems during spring grinding.

Allgaier Automotive GmbH, Mühlhausen - Germany

FEINGUSS BLANK GmbH, Riedlingen - Germany

Deutsche Edelstahlwerke Specialty Steel GmbH & Co. KG, Witten - Germany

Johne Karosseriebau-Blechbearbeitung, Leingarten - Germany

Stryker Leibinger GmbH & Co. KG, Freiburg - Germany

... and many more!

Links

Used products

Dry separator VARIO eco >>

Dry separator PT-Filter >>

Pre-Separators >>

Capturing devices >>

Filter element KLR-Filter >>

Set and guidelines

TA-Luft: Air pollution control - emission standards >>

42. BImSchV: Avoiding legionella risk in wet scrubbers >>

VDI 2262-3: Air quality in the workplace - clean air recirculation >>

TRGS 900: Occupational limit values in the workplace >>

TRGS 561: Processing of carcinogenic metals >>

TRGS 528: Welding operations >>

DGUV-Regel 109-001 (fomerly: BGR 109): Grinding, brushing and polishing of aluminum >>

DGUV-Regel 109-002 (formerly: BGR 121): Workplace ventilation >>

DGUV-Regel 109-011 (formerly: BGR 204): Magnesium processing >>

1999/92/EG (formerly: ATEX 137): Explosion Protection Directive for Operators >>

2014/34/EU (formerly: ATEX 114): Explosion Protection Directive for Manufacturers >>

EN 1127-1: Explosive environments >>

TRBS 727: Avoiding ignition hazards created by electrostatic charges >>

VDI 2263-6: Fire and explosion protection for dust extraction systems >>