Suitable filter technology for any application

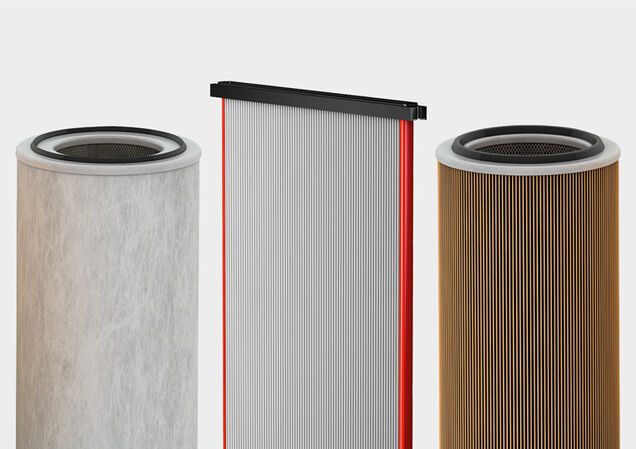

This is an overview of our product range of filter elements. Our portfolio includes all popular extraction filters - both dry filter elements such as filter plates, cartridge filters or filter hoses, as well as filter elements for oil and coolant mist separation, such as cartridge filters or demisters.

If you are searching for filter replacements, you will find more information regarding our after-sales service here:

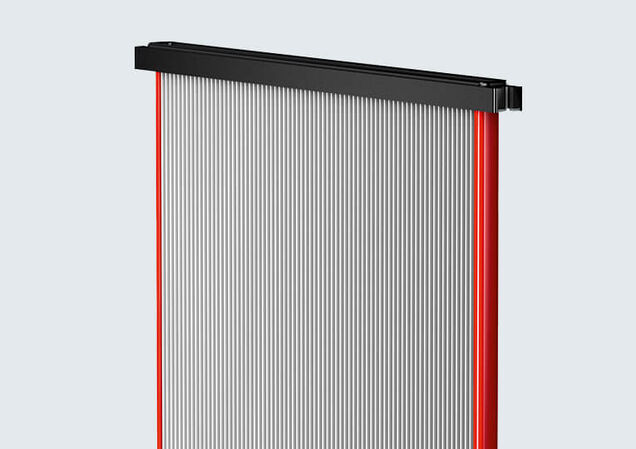

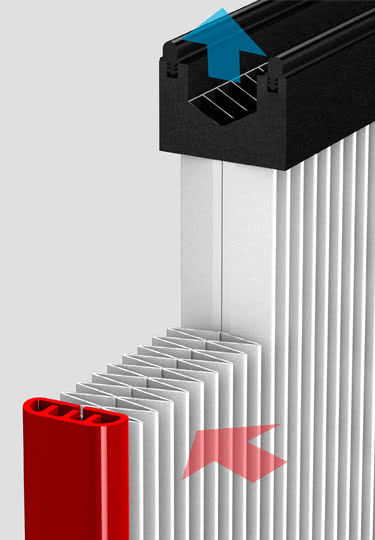

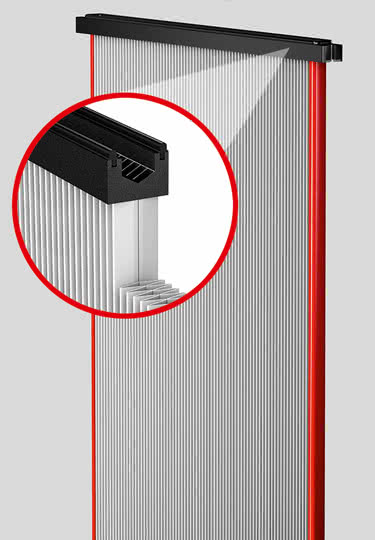

KLR-Filter: High-performance filter elements for separating a variety of process emissions

KLR stands for Keller Long Run. The long service life of the filter elements (up to 20000 operating hours) provides maximum process reliability and minimizes production downtimes, maintenance efforts, and spare parts and waste disposal costs, as well.

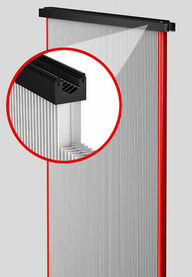

Surface filtration and compressed air pulse cleaning of the filter elements during operation ensure a nearly constant air capacity and continuous operation even for high dust volumes.

Long service life with reduced energy consumption

All characteristic elements of this new Keller design were optimized as compared to the market standard. The service life increased by up to 120.000 cleaning intervals, with a simultaneous reduction in energy consumption. A beneficial result in every respect!

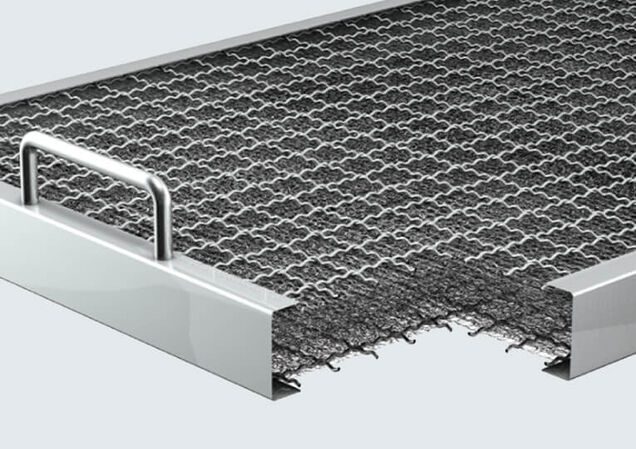

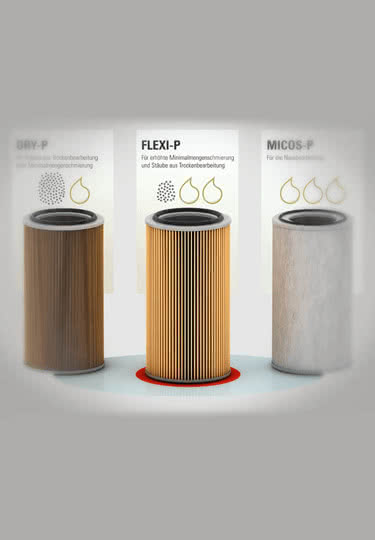

FLEXI-P: Cartridge filter for minimum quantity lubrication (MQL) - totally effective in a variety of processes

Metal dust, shavings and oil mist are frequently created on machine tools using minimum quantity lubrication. In practice it is difficult to determine which air contaminant will come into play, therefore, customers have had to choose between either a dry separator for dust and shavings or a separate coolant or oil mist separator. For greater flexibility in the future with increasingly complex separation challenges posed by metalworking machines, Keller now offers the universally applicable FLEXI-P cartridge filter.

Increased service life and low investment risk

A data analysis performed by Keller specialists has determined that oil mist poses a considerable problem in supposed "dry" processes. Anyone using inappropriate filters for these processes usually experiences a greatly reduced service life of the after-filters. FLEXI-P has been shown to successfully increase their service life by tenfold.

Low Investment risk, greater flexibility: Choosing FLEXI-P substantially reduces initial equipment investment costs, especially when a machining process changes, the associated separation system needs no additional modifications.