Safety and efficiency when manufacturing solid dosage forms in the pharmaceutical & chemical industries

Capsules and/or tablets are among the most commonly used forms of medication and dietary supplements. They are solid dosage formulations produced by compounding active ingredients and excipients under high pressure. Various granulates or powder blends are used in this process, which is why it is particularly important not only to ensure quantity accuracy in their production, but also to guarantee the release of active ingredients into the body through the recommended dosage.

For plant operators it is, therefore, essential to meet the highest quality standards while ensuring efficient and cost-effective production processes.

A significant component of the compression process in dry powder formulations, which is often undervalued, is the extraction system. These systems perform a key function in ensuring a healthy and safe working environment.

When compressing tablets, fine powdery particulate and dust are released, not only affecting the quality of the final product, but also posing a potential health hazard to the workforce. There is also a risk of airborne particles settling on machinery and systems, thereby impairing production efficiency and increasing servicing and cleaning costs.

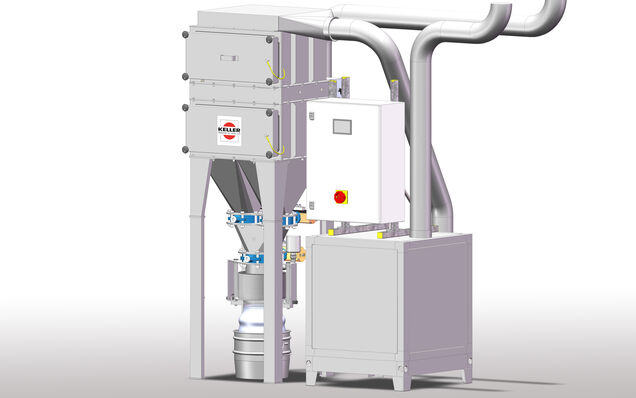

The universal (H)EPA dry separator in compact format

State-of-the-art extraction systems, such as the Keller PCF-1 (H)EPA dry separator with zero-contamination discharge, have proven to be indispensable in pharmaceutical and nutraceutical production.

They not only ensure compliance with statutory regulations and occupational health and safety standards, but also improve product quality by preventing contamination. The high-efficiency extraction systems from Keller are renowned for their quality and excellent price-performance ratio. They are compliant with strict manufacturing-related quality standards and optimize the efficiency and cost-effectiveness of their production processes, especially regarding the disposal of separated dust.

For operators, investing on the new Keller PCF-1 (H)EPA dry separator is ultimately an intelligent choice.