Clean air for hardening shops

When metals are hardened, very different processes are used, leading to significantly different requirements for exhaust air filtration. In principle, salt bath hardening, induction hardening and gas hardening are all different methods. Common to all these processes, however, are the dual steps of heating the workpieces and their rapid cooling.

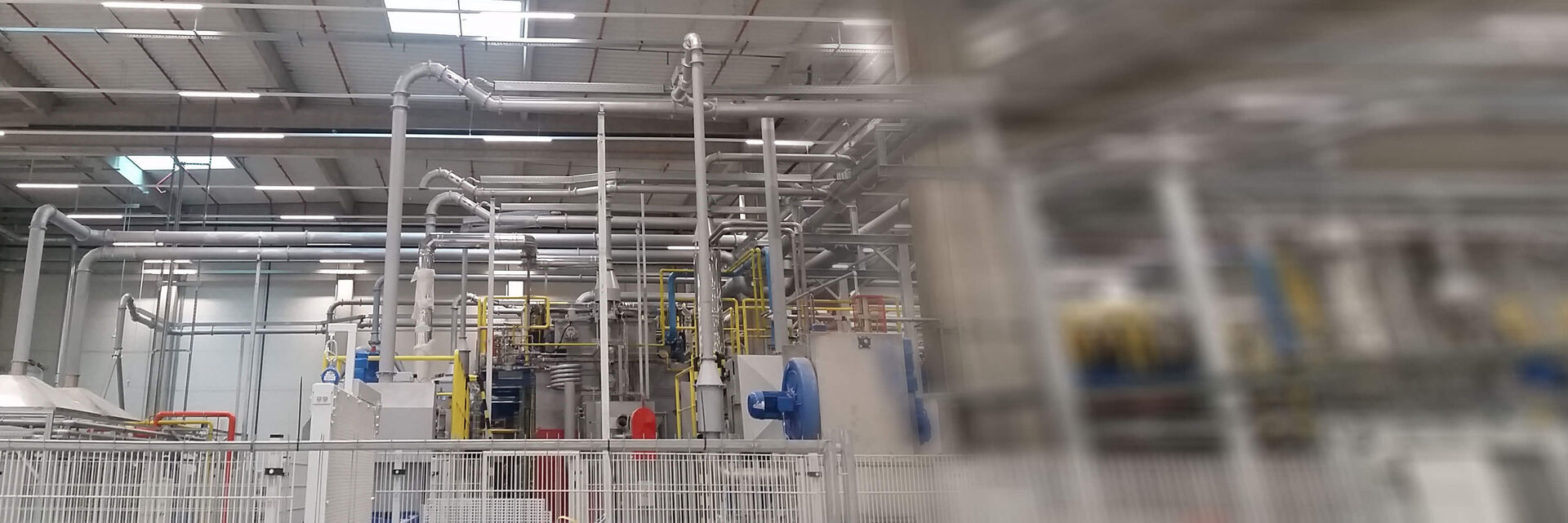

The suitable extraction solution for any application

Either dry or wet systems can be used for salt bath hardening processes, depending on the salt used and the application. As a rule, the dust can be extracted using a dry operating system, which is more energy efficient. However, if aqueous dousing solutions are used, a wet system is recommended due to the moisture content.

During induction hardening, the products are quickly heated in a machine and simultaneously drenched with a water-miscible high temperature oil. Keller coolant mist separators are equipped with a specially designed cleaning system for automatic filter element cleaning, thereby enabling an uninterrupted production process. They are particularly suitable for exhaust air contaminated with highly-viscous aerosols.

Gas hardening processes use wet separators with pre-spraying to minimize the fire risk posed by open flames inside the systems. By quenching with water after collection, the ductwork is protected from a potential fire.

"Hardening shop benefits from Keller Lufttechnik After-Sales Service"

To the success storyReferences Hardening

These customers rely on our extraction systems during hardening.

Haas Metallguß GmbH, Mühlhausen im Täle - Germany

Gewinde Satelliten Antriebe AG, Horriwil - Switzerland

Mubea - Muhr und Bender KG, Attendorn - Germany

Metaldyne Oslavany, spol. s r.o., Oslavany - Czech Republic

... and many more!

Links

Used products

Dry separator JET-SET >>

Venturi wet separator VDN >>

Explosion protection

Information about "explosion protection according to ATEX" >>

Set and guidelines

TA-Luft: Air pollution control - emission standards >>

42. BImSchV: Avoiding legionella risk in wet scrubbers >>

VDI 2262-3: Air quality in the workplace - clean air recirculation >>

TRGS 900: Occupational limit values in the workplace >>

TRGS 561: Processing of carcinogenic metals >>

TRGS 528: Welding operations >>

DGUV-Regel 109-001 (fomerly: BGR 109): Grinding, brushing and polishing of aluminum >>

DGUV-Regel 109-002 (formerly: BGR 121): Workplace ventilation >>

DGUV-Regel 109-011 (formerly: BGR 204): Magnesium processing >>

1999/92/EG (formerly: ATEX 137): Explosion Protection Directive for Operators >>

2014/34/EU (formerly: ATEX 114): Explosion Protection Directive for Manufacturers >>

EN 1127-1: Explosive environments >>

TRBS 727: Avoiding ignition hazards created by electrostatic charges >>

VDI 2263-6: Fire and explosion protection for dust extraction systems >>