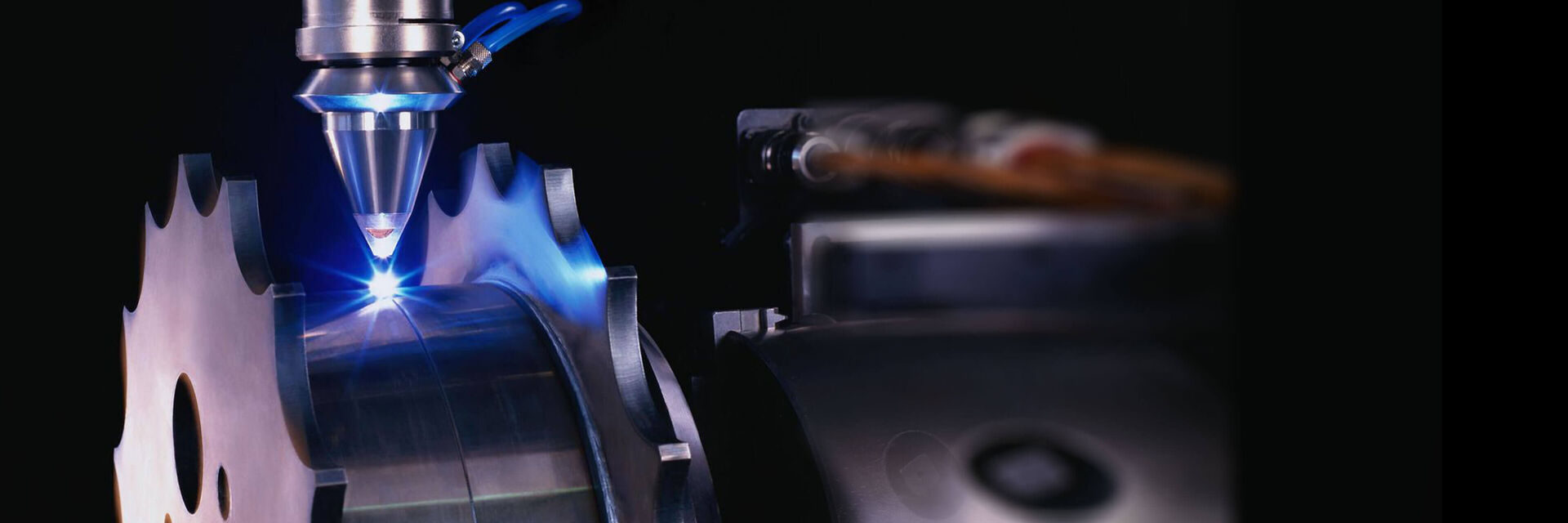

Clean air for laser welding

Laser technology is now standard in the machining industry for metal welding. The resultant increase in precision and productivity is also associated with an increased emission of pollutants, sometimes in the submicroscopic range. This affects the well-being of the operator and the functioning of the laser system. Consequently, a dust extraction system is required to ensure effective dust collection and separation.

Safe dry separation

Dry separators in the VARIO, PT-filters or L-CUT series are most suitable for very fine particulate.

The system design can be flexible with regard to the required airflow and individual processes because of the diverse filter series - also feasible for large air flows.

For thermal processes such as laser engraving, additional fire protection measures should be considered, as well as explosion protection in accordance with ATEX regulations.

References laser welding

These customers rely on our extraction systems during laser welding.

Volkswagen AG., worldwide (Welding in the body shop )

SAUER DMG, Pfronten - Germany (Laser machining centers )

... and many more!

Links

Used products

Dry separator VARIO eco >>

Dry separator PT-Filter >>

Dry separator L-CUT >>

Filter element KLR-Filter >>

Explosion protection

Information about "explosion protection according to ATEX" >>

Set and guidelines

TA-Luft: Air pollution control - emission standards >>

VDI 2262-3: Air quality in the workplace - clean air recirculation >>

TRGS 900: Occupational limit values in the workplace >>

TRGS 560: Air recirculation after processing carcinogenic dust >>

TRGS 561: Processing of carcinogenic metals >>

TRGS 528: Welding operations >>

DGUV-Regel 109-002 (formerly: BGR 121): Workplace ventilation >>