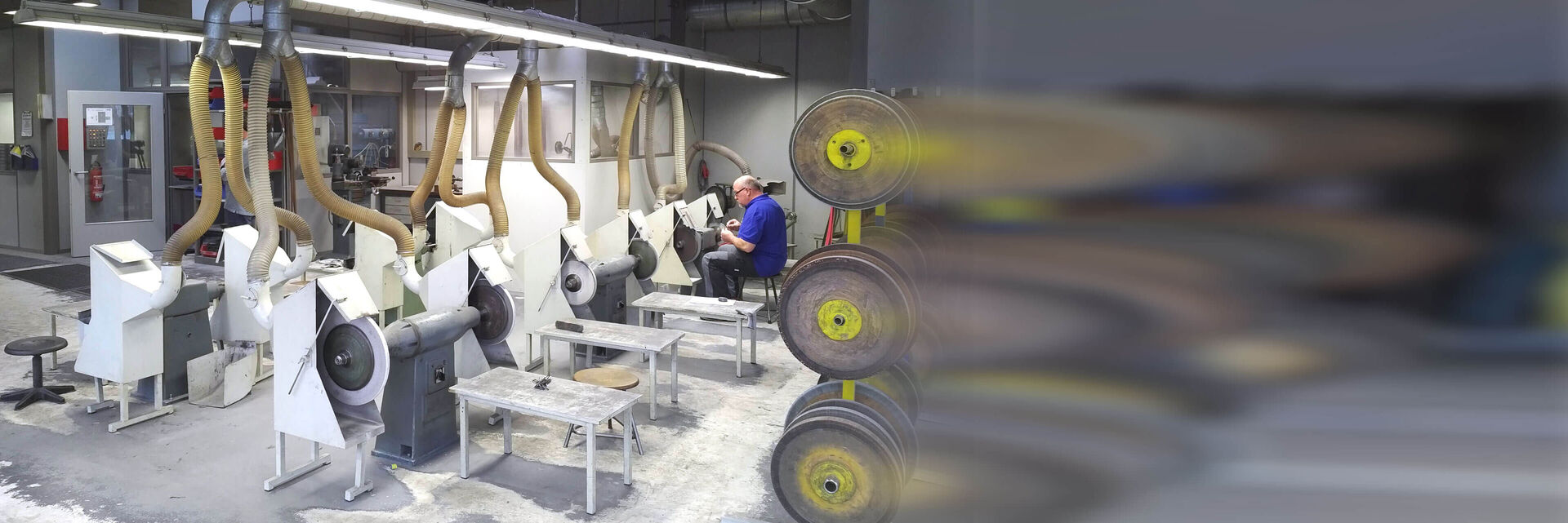

Clean air during surface treatment

Polishing emits fine particulate which is almost impossible to prevent even with the most advanced production technologies.

Besides polishing dusts, polishing paste, substrate such as scrubbing fleece (cotton, other), and additional by-products of abrasion are suctioned off. Since these dusts are explosive and combustible, preventive explosion and fire protection measures should be included in the final design for dry separation.

Customized dust extraction technologies with explosion protection and feasible clean air recirculation

Dust extraction can be specially designed for your requirements using either dry or wet separation.

For dry separation processes units in the VARIO and PT series are recommended. However investment costs for wet separators in the VDN series are more economical.

KLR bran filters and additional secondary filters, depending on the requirement, are employed if purified air is recirculated back into the workplace. The service life of a filter can also be prolonged with the additional pre-separation of coarse dust particles utilizing cyclones.

A dosing unit adds limestone powder to reduce the fire and explosion risk during dry separation. Further explosion protection measures can be omitted, however the mixing ratio should remain at 9:1.

Strategies for dust extraction from blasting and brushing processes

Download BrochureReferences Polishing

These customers rely on our extraction systems during metal polishing.

Hoppe AG, Chomutov - Czech Republic

Keuco GmbH & Co. KG, Hemer - Germany

W-Finish GmbH & Co. KG - Witt Metallschleiferei, Schwelm - Germany

WMS Oberflächenbearbeitung, Wittlich - Germany

DURA Automotive Portuguesa Lda., Carregado - Portugal

aha Albert Haag GmbH, Korschenbroich - Germany

Oerlikon Balzers Coating Germany GmbH, Balzers - Switzerland

... and many more!

Links

Used products

Dry separator VARIO eco >>

Venturi wet separator VDN >>

Compact wet separator HydronPlus >>

Capturing devices >>

Pre-Separators >>

Filter element KLR-Filter >>

Explosion protection

Information about "explosion protection according to ATEX" >>

Back pressure flap ProFlap >>

Set and guidelines

TA-Luft: Air pollution control - emission standards >>

42. BImSchV: Avoiding legionella risk in wet scrubbers >>

VDI 2262-3: Air quality in the workplace - clean air recirculation >>

TRGS 900: Occupational limit values in the workplace >>

TRGS 561: Processing of carcinogenic metals >>

TRGS 528: Welding operations >>

DGUV-Regel 109-001 (fomerly: BGR 109): Grinding, brushing and polishing of aluminum >>

DGUV-Regel 109-002 (formerly: BGR 121): Workplace ventilation >>

DGUV-Regel 109-011 (formerly: BGR 204): Magnesium processing >>

1999/92/EG (formerly: ATEX 137): Explosion Protection Directive for Operators >>

2014/34/EU (formerly: ATEX 114): Explosion Protection Directive for Manufacturers >>

EN 1127-1: Explosive environments >>

TRBS 727: Avoiding ignition hazards created by electrostatic charges >>

VDI 2263-6: Fire and explosion protection for dust extraction systems >>