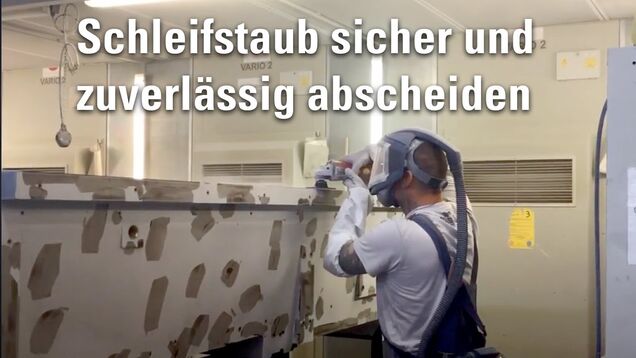

Dedusting systems for grinding work booths and work stations

Grinding of metals and non-ferrous metals produces fine dust particles which even while using the most advanced production technologies are impossible to prevent. Collecting and removing these fine dusts using suction is often required for technological, product-specific, environmental and regulatory reasons.

Handling these fine dust particles can pose a health hazard, stainless steel dust (e. g. processing of chrome and nickel) can be carcinogenic.

The potential risk of fire and explosion presents additional requirements for a suitable explosion and fire protection plan. Special precautions must be taken with light metals such as aluminum and magnesium, which possess a high Kst-value and are mostly classified as dust category St 1 - St3.

Customized dust extraction technologies with explosion protection and feasible clean air recirculation

Depending on the type of dust, and the method of fire and explosion protection, extraction can be by either a dry or wet separation system.

Which type of extraction should be used depends on whether the purified air will be recirculated back into the plant or vented outdoors. Wet separators involve lower initial investment costs, whereas dry separators provide advantageous lower operating costs.

Fire and explosion protection methods are required if the dust is combustible or explosive.

Additional secondary filters must be installed when processing stainless steel because of the carcinogenic qualities of the dust.

Strategies for dust extraction from blasting and brushing processes

Download BrochureReferences Grinding Metals

These customers rely on our extraction systems during grinding of metals and non-ferrous metals.

Allgaier Automotive GmbH, Mühlhausen - Germany

FEINGUSS BLANK GmbH, Riedlingen - Germany

Deutsche Edelstahlwerke Specialty Steel GmbH & Co. KG, Witten - Germany

Johne Karosseriebau-Blechbearbeitung, Leingarten - Germany

Stryker Leibinger GmbH & Co. KG, Freiburg - Germany

... and many more!

Links

Used products

Dry separator VARIO eco >>

Dry separator PT-Filter >>

Dry separator L-CUT >>

Single separator TR-1 >>

Venturi wet separator VDN >>

Compact wet separator HydronPlus >>

Capturing devices >>

Filter element KLR-Filter >>

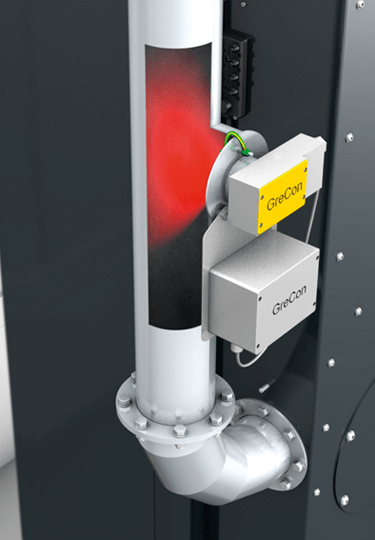

Explosion protection

Explosion protection Information about "explosion protection according to ATEX" >>

Back pressure flap ProFlap >>

Flameless pressure relief ProPipePlus >>

Set and guidelines

TA-Luft: Air pollution control - emission standards >>

42. BImSchV: Avoiding legionella risk in wet scrubbers >>

VDI 2262-3: Air quality in the workplace - clean air recirculation >>

TRGS 900: Occupational limit values in the workplace >>

TRGS 561: Processing of carcinogenic metals >>

TRGS 528: Welding operations >>

DGUV-Regel 109-001 (fomerly: BGR 109): Grinding, brushing and polishing of aluminum >>

DGUV-Regel 109-002 (formerly: BGR 121): Workplace ventilation >>

DGUV-Regel 109-011 (formerly: BGR 204): Magnesium processing >>

1999/92/EG (formerly: ATEX 137): Explosion Protection Directive for Operators >>

2014/34/EU (formerly: ATEX 114): Explosion Protection Directive for Manufacturers >>

EN 1127-1: Explosive environments >>

TRBS 727: Avoiding ignition hazards created by electrostatic charges >>

VDI 2263-6: Fire and explosion protection for dust extraction systems >>