Reliable extracion of finest chippings, fibers and particulate

All machining processes with GRP (fiberglass) and CFC (Chlorofluorocarbon) produce very fine fragments, fibers and particulate depending on the material being processed. These dust aerosols can negatively impact human health. They can also inhibit the efficiency of machine tools and plant equipment. A static electricity discharge presents a potential fire and explosion risk, as well. These are among the reasons why process dust from composites should be collected and discharged carefully.

The issues of ambient air decontamination during GRP/CFC mold processes, prevention of damage from a dust explosion, and the possible re-use of energy from process exhaust air, can present highly complex topics which must also take into consideration applicable regulations and recommendations.

Typical fields of application for the machining of composites are amongst other the airplane and helicopter construction, production of wind power plants as well as car body production.

Air pollution control to protect human health and equipment - using explosion protection and measures for clean air recirculation

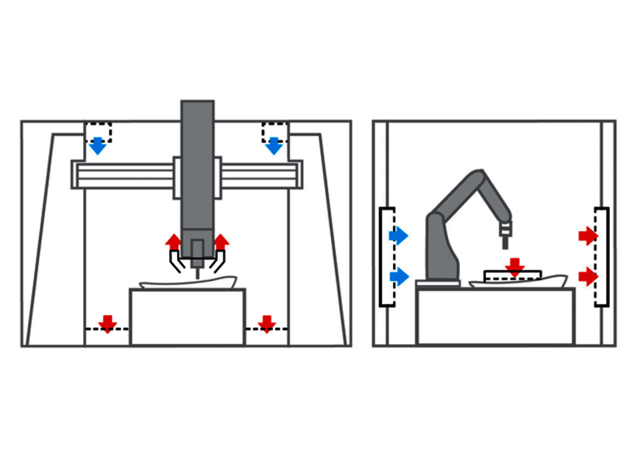

For the dust extraction during the treatement of composites are basically used dry separators of the series VARIO, PT and L-CUT. In conjunction with components for fire and explosion protection is guaranteed a high process safety. The high separation efficiencies of the KLR filters enable clean air recirculation.

Extraction of dust created during fabrication of GRP and CFC composite molds

Download BrochureEfficient solutions for milling airplane flaps at GKN Aerospace

Articel costumer magazineLinks

Used products

Dry separator VARIO eco >>

Pre-Separators >>

Filter element KLR-Filter >>

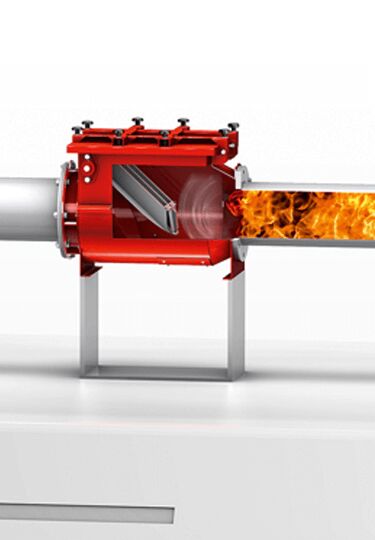

Explosion protection

Information about "explosion protection according to ATEX" >>

Back pressure flap ProFlap >>

Flameless pressure relief ProVent >>

Set and guidelines

TA-Luft: Air pollution control - emission standards >>

VDI 2262-3: Air quality in the workplace - clean air recirculation >>

TRGS 900: Occupational limit values in the workplace >>

DGUV-Regel 109-002 (formerly: BGR 121): Workplace ventilation >>

1999/92/EG (formerly: ATEX 137): Explosion Protection Directive for Operators >>

2014/34/EU (formerly: ATEX 114): Explosion Protection Directive for Manufacturers >>

EN 1127-1: Explosive environments >>

TRBS 727: Avoiding ignition hazards created by electrostatic charges >>

VDI 2263-6: Fire and explosion protection for dust extraction systems >>